Project Type

Deconstruction & Demolition

29 Ranui Street, Picton

91.47% Waste Diversion on a Unique Home Demolition

Unique Home Demolition

29 Ranui Street, Picton

Location

Picton

Completion Date

2025

29 Ranui Street, Picton

91.47% Waste Diversion on a Unique Home Demolition

At Scope Group, every demolition is an opportunity and not just to clear the way for something new, but to do so responsibly. Our recent project at 29 Ranui Street, Picton was no exception, and in fact, it presented a unique challenge that turned into one of our most rewarding jobs to date.

A House Built From Polystyrene Panels

Unlike typical residential structures, this home was built using polystyrene panel construction a method that’s rare in our region and posed some interesting logistical and environmental considerations. The home was scheduled for removal to make way for a new build, and we saw it as a chance to do something different.

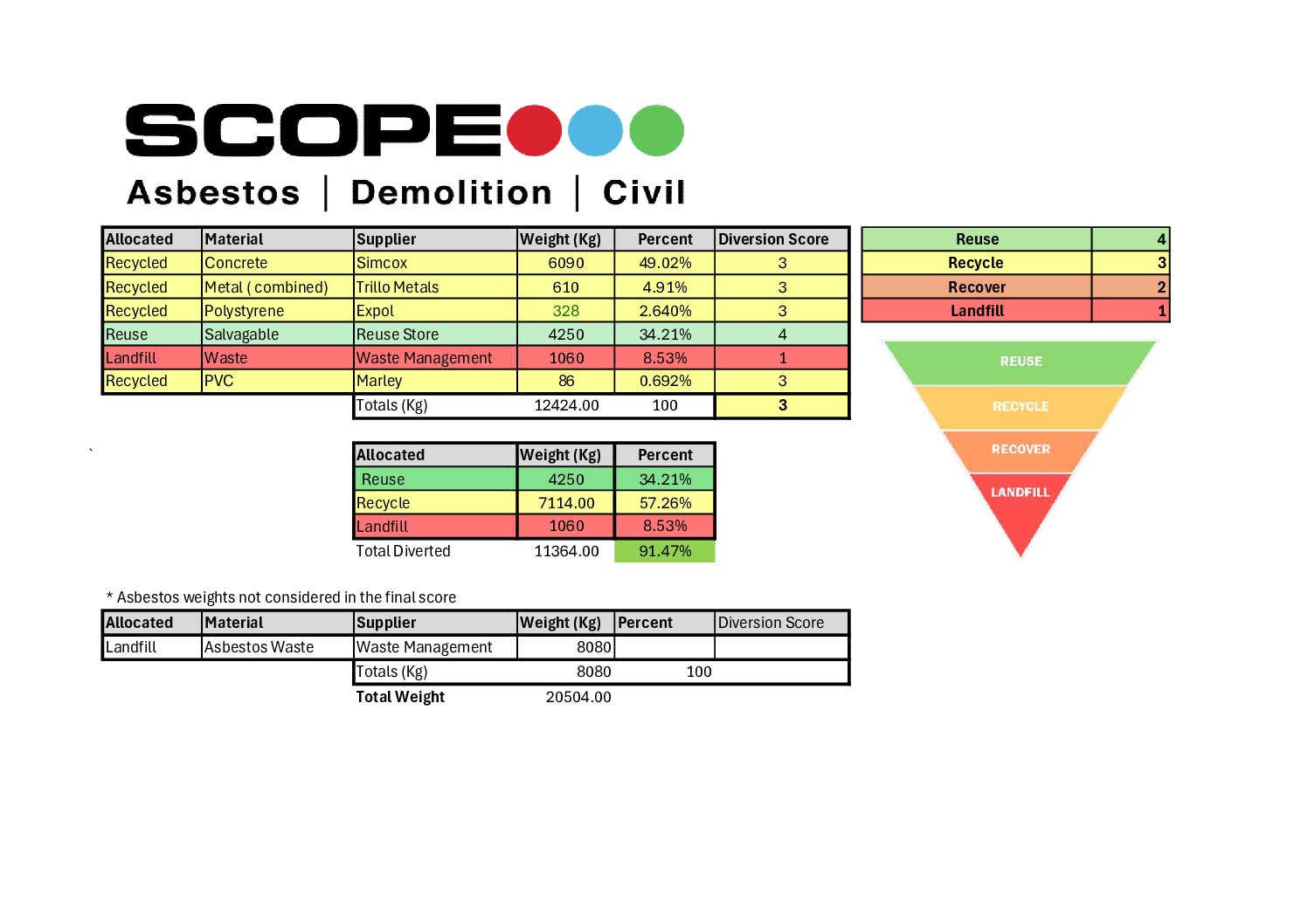

Rather than send it all to landfill, we committed to careful material separation, community reuse, and responsible recycling. The result? A waste diversion rate of 91.47% with the vast majority of the structure given a second life.

What Was Diverted and Where It Went

Polystyrene Panels

The standout feature of the house was its panel system the large sheets of polystyrene sandwiched between facings. Many of these panels were still in excellent condition and were donated to a local reuse charity, they were repurposed and sold to support community initiatives.

Metal

The roofing iron, panel support brackets and balcony balustrade were stripped and sent off for metal recycling. We went the extra mile by collecting all the screws and nails into buckets for proper separation. Even the internal copper plumbing pipes were carefully removed and sorted from the general scrap metal, ensuring they could be recycled through the appropriate channels.

Windows, Doors & Fixtures

We used a Hi-ab truck to lift the stair way out in one piece as well as the garage door. All salvageable windows, doors, light fittings, and timber beams were carefully removed and passed on to the reuse store, where they’ll now find new homes in other buildings or DIY projects.

Concrete

The driveway and foundation piles were taken to a local crushing plant for reuse as aggregate in future construction keeping bulk waste out of landfill and reducing the need for virgin materials being extracted from quarries and river beds.

Damaged Materials

Not everything could be saved, of course. Some polystyrene panels were too damaged for reuse. We made sure to separate the polystyrene from timber, and transported it to Christchurch where it could be properly recycled a step that required extra care but aligned with our waste minimization goals.

A Hands-On Approach

The project ran for three weeks, and in keeping with our reuse-first mindset, hand tools were used throughout the deconstruction phase. This was important to protect the panels so they went to their new home in good shape. Only once we reached the concrete did we bring in heavier equipment.

This type of polystyrene house was a first for our team and they rose to the occasion. It required them to think differently, work precisely, and stay focused on sustainability throughout the process. They genuinely took ownership of the challenge, and the outcome speaks for itself.

Lessons Learned & Looking Ahead

This demolition wasn’t just about clearing a site, it was a learning experience for the entire team. It showed us what’s possible when sustainability is embedded from the outset and reinforced how critical good planning, team buy-in, and smart material separation are to achieving meaningful results.

We’re proud of the 91.47% diversion rate, but even prouder of the mindset it represents. This project has set a new benchmark for us moving forward, and we’re excited to keep pushing the limits of what responsible demolition can look like.